Plates & Coils

In many different industries, especially in manufacturing, construction, and fabrication, metal is produced and supplied primarily in two forms: plates and coils. Here's a brief overview of each:

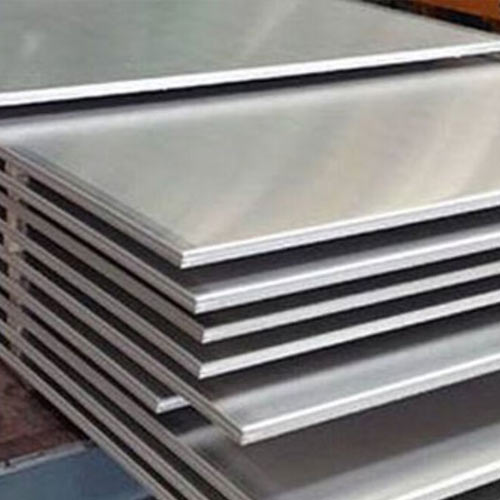

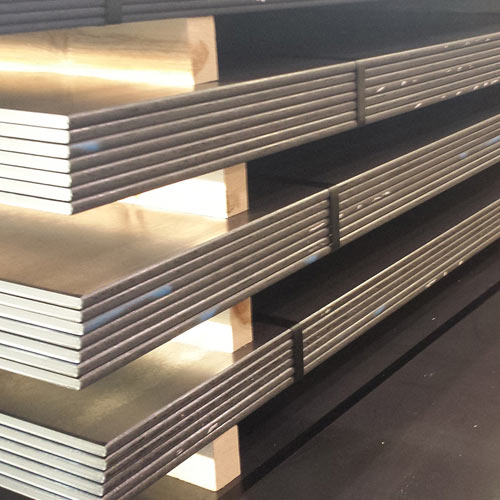

Plates

- Plates are rectangular-shaped metal sheets that are flat and have a constant thickness all over.

- In order to achieve the appropriate dimensions and reduce thickness, a slab of metal is usually passed through rolling mills during the production process.

- Plates are available in a variety of sizes and thicknesses, from thin sheets used in automotive panels to thick plates used in heavy machinery and construction.

- Stainless steel, titanium, steel, and aluminum are a few common materials for plates.

- Plates are frequently shaped and cut into precise shapes to meet the needs of various applications, including architectural elements, machinery parts, and structural components.

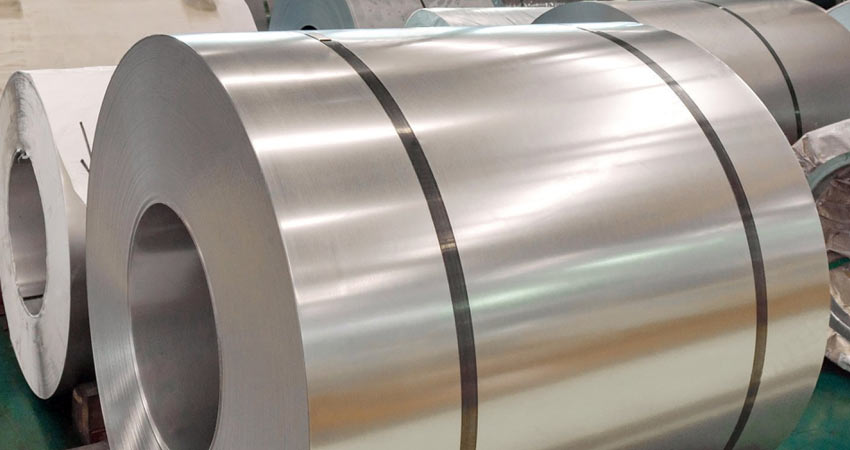

Coils

- Continuous metal strands coiled into a cylindrical form are called coils. They are made by a procedure known as coil rolling or coil slitting, in which a big metal strip is repeatedly rolled or sliced into coils with different thicknesses and widths.

- Coils are frequently used in processes, metal forming, and coil-based products including electrical components, HVAC systems, and automobile parts, among other applications that call for continuous lengths of metal.

- Coils are constructed from a range of materials, such as alloys, steel, aluminum, and copper, just like plates. In order to manufacture unique forms and components for different sectors, coils are frequently subjected to additional processing, such as stamping, cutting, or molding.

- A multitude of industries depend on plates and coils as vital raw materials, and their diversity in sizes, grades, and finishes permits a high degree of adaptability.